Table of Contents

How Hydraulic Cylinders Power Modern Automation Systems

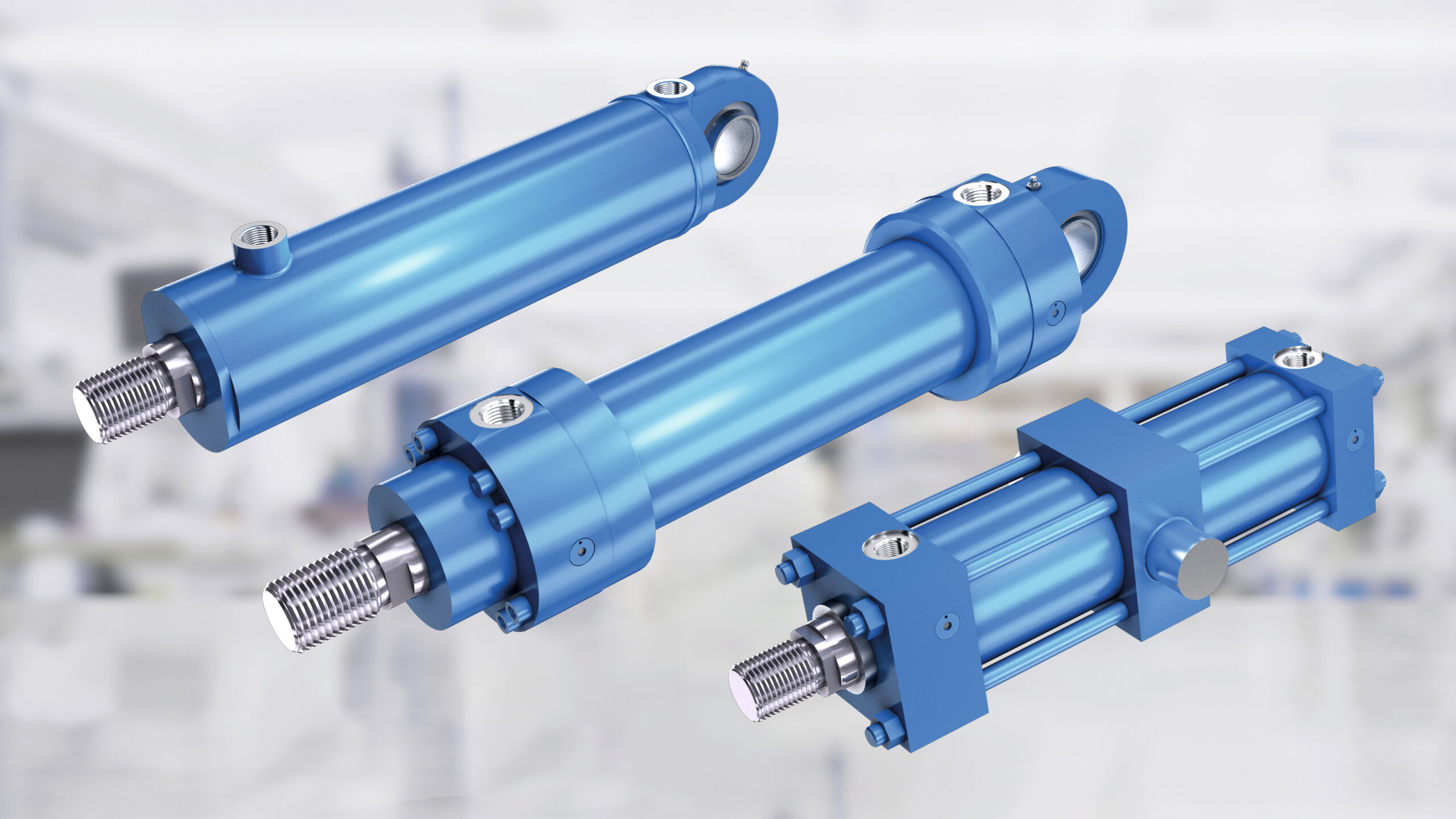

In the ever-evolving world of industrial automation, hydraulic cylinders continue to play a foundational role. These mechanical actuators, known for their powerful linear force and precision control, are essential components in systems that demand efficiency, strength, and reliability. From manufacturing lines and robotics to construction equipment and aerospace applications, hydraulic cylinders are powering the backbone of modern automation systems.

Understanding Hydraulic Cylinders

According to a Hydraulic Cylinders Market report, the industry is expected to grow significantly in the coming years.

Hydraulic cylinders are devices that convert fluid power into linear mechanical force and motion. They function by pressurizing hydraulic fluid—usually oil—inside a closed cylinder, which pushes a piston and generates movement. This basic principle of fluid mechanics enables immense force with relatively small components.

There are several types of hydraulic cylinders, including:

- Single-acting cylinders, where the fluid acts on one side of the piston only.

- Double-acting cylinders, where the fluid applies pressure on both sides for controlled motion in both directions.

- Telescopic cylinders, used when long strokes are required but space is limited.

- Tie-rod and welded cylinders, each designed for different levels of durability and customization.

Regardless of their configuration, hydraulic cylinders offer superior strength-to-size ratios, making them ideal for high-force applications in compact spaces.

Why Are Hydraulic Cylinders Integral to Automation?

Modern automation systems rely on accuracy, repeatability, and high throughput. Hydraulic cylinders meet these demands in several key ways:

1. High Force Output

Hydraulic cylinders can generate immense force, often reaching thousands of pounds of pressure. This makes them suitable for heavy-duty operations like pressing, lifting, clamping, or bending—tasks frequently encountered in industrial automation systems.

2. Precision Control

Advanced hydraulic systems incorporate sensors and servo valves that allow for precise control of speed, position, and force. These features are essential in automated processes where even minor deviations can lead to defects or system errors.

3. Compact Design

Compared to other linear actuators, such as electric or pneumatic cylinders, hydraulic systems can deliver higher force in a more compact form factor. This is particularly beneficial in space-constrained environments, such as robotic arms or mobile machinery.

4. Durability and Reliability

Hydraulic cylinders are built to withstand harsh environments and operate under extreme conditions. Their rugged design and resistance to dust, water, and temperature fluctuations make them ideal for use in automation systems exposed to outdoor or industrial elements.

Real-World Applications in Automation

Hydraulic cylinders are found across a wide array of automation-driven industries. Here’s a look at how they contribute to various sectors:

1. Manufacturing and Assembly Lines

In automotive and electronics assembly lines, hydraulic cylinders automate tasks such as stamping, welding, lifting, and pressing. With programmable motion control, they ensure consistency and repeatability, which is vital for quality assurance in mass production.

2. Material Handling

Hydraulic actuators are extensively used in conveyor systems, scissor lifts, and robotic grippers. These systems rely on precise movement and substantial lifting capacity, particularly in warehouses and logistics centers where goods need to be moved efficiently.

3. Construction and Earthmoving Equipment

Excavators, loaders, and bulldozers use hydraulic cylinders to control booms, arms, and buckets. As automation expands into construction—such as autonomous earthmovers and remote-controlled cranes—hydraulic systems remain at the core of their operation.

4. Aerospace and Defense

Hydraulic cylinders operate landing gear, flight control surfaces, and cargo doors in aircraft. Automation in aerospace requires actuators that can operate under high pressure and in extreme environments, conditions in which hydraulic cylinders excel.

5. Agricultural Machinery

From automated harvesters to seeders and sprayers, hydraulic systems support the automation of agriculture by enabling complex, repetitive tasks with high reliability and low energy consumption.

Integration with Smart Technologies

Today’s automation systems are increasingly integrating smart technologies like sensors, the Internet of Things (IoT), and data analytics. Hydraulic cylinders have kept pace by evolving into smart hydraulic actuators.

Smart hydraulic cylinders come equipped with:

- Position sensors for real-time tracking of piston movement.

- Pressure sensors to monitor system load and fluid performance.

- Temperature sensors to prevent overheating and ensure optimal performance.

These features allow operators to collect data, monitor cylinder health, and implement predictive maintenance strategies—significantly reducing downtime and increasing productivity.

Benefits of Hydraulic Cylinders in Modern Automation

Let’s summarize the key advantages hydraulic cylinders offer to today’s automation environments:

- Power Density: Capable of delivering high force from a small package.

- Speed and Accuracy: Adjustable speed and position control enhance performance.

- Longevity: Built for durability, reducing long-term operational costs.

- Adaptability: Customizable for various applications and industries.

- Integration Readiness: Easily integrated with digital control systems for smart automation.

The Future of Hydraulic Automation

As automation systems become more sophisticated, the role of hydraulic cylinders will continue to expand. Innovations like electro-hydraulic actuators, which combine electric control with hydraulic power, are bridging the gap between traditional hydraulics and fully digital systems.

Additionally, advancements in energy-efficient hydraulics—such as variable-speed pumps and closed-loop systems—are reducing energy consumption and environmental impact, making hydraulic automation more sustainable.

Conclusion

Hydraulic cylinders may be rooted in traditional mechanical engineering, but they are far from outdated. With advancements in smart control, integration with IoT, and improvements in energy efficiency, these powerful actuators are more relevant than ever in driving modern automation.

Whether lifting massive loads on a factory floor or executing precision tasks in robotic systems, hydraulic cylinders remain indispensable in making automation smarter, faster, and stronger.