In the world of powder coating, achieving a flawless finish is the ultimate goal. Whether you are coating automotive parts, industrial equipment, or household appliances, the quality of the finish can make or break the product’s overall appeal. While several factors contribute to a successful powder coating process, one often underestimated aspect is the design of the blast booth. In this blog post, we will delve into the critical role that blast booth design plays in powder coating results. From surface preparation to integration with curing ovens, each aspect of blast booth design has a profound impact on the outcome.

Table of Contents

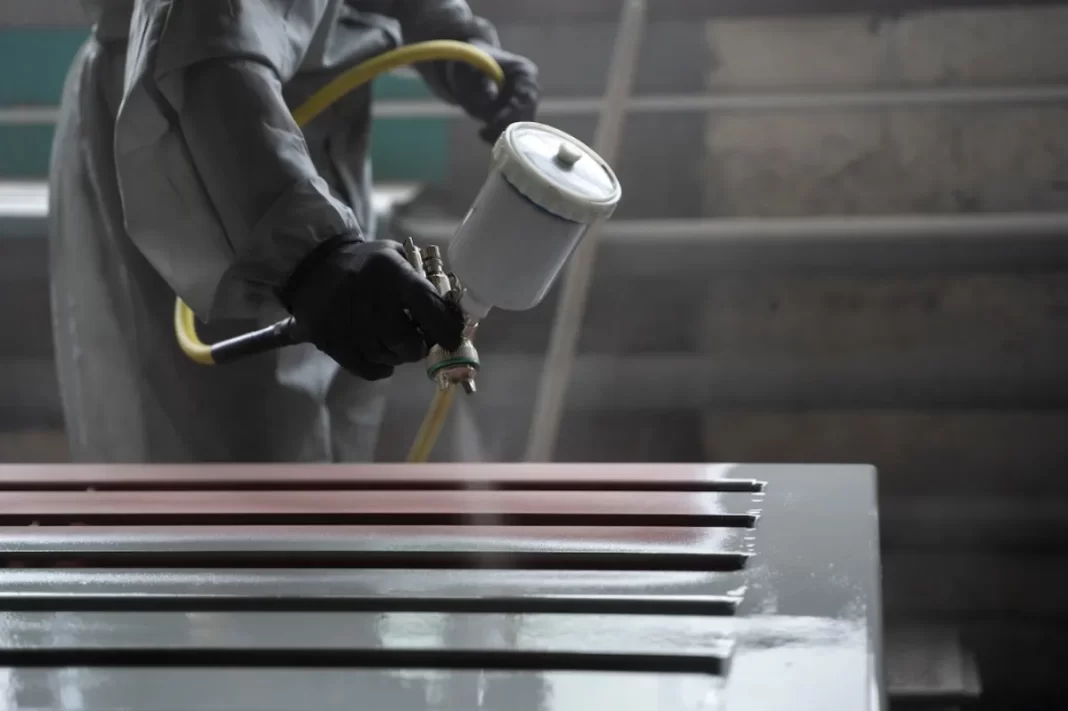

Surface Preparation for Adhesion

Surface preparation is the foundation of a successful powder coating process. Without proper preparation, the powder coating may not adhere to the substrate as desired. The design of the blast booth plays a crucial role in this phase. A well-designed sandblasting booth ensures that the surface is thoroughly cleaned, removing rust, paint, and contaminants. This not only promotes adhesion but also extends the lifespan of the coating.

Controlling Contaminants

Contaminants can be the nemesis of powder coating. Even the tiniest particle can mar the finish, leading to imperfections. Blast booth design should incorporate effective contaminant control mechanisms. This includes proper filtration systems and airflow management to prevent dust and debris from settling on the surface during blasting. By minimizing contaminants, the quality of the powder coating is significantly enhanced.

Optimizing Workflow

Efficiency in the powder coating process is essential for both productivity and cost-effectiveness. Blast booth design can greatly impact workflow optimization. This includes the layout of the booth, the positioning of the blasting equipment, and the accessibility of workpieces. A well-thought-out design can streamline the process, reducing downtime and ensuring a smoother operation.

Consistent Media Velocity

Achieving a uniform and consistent finish across all parts is a hallmark of quality powder coating. The design of the blast booth must ensure consistent media velocity. This means that the abrasive media used for blasting should be delivered at a consistent speed and pressure. Variations in media velocity can result in uneven coating thickness and appearance issues.

Visibility for Monitoring Progress

Monitoring the progress of the blasting process is crucial for quality control. Blast booth design should incorporate features that provide visibility to the operator. This includes proper lighting and clear viewing windows. With better visibility, operators can spot and address any issues promptly, ensuring that the coating process proceeds smoothly.

Adjustable Components

Flexibility in blast booth design is essential to accommodate a wide range of workpieces. Adjustable components such as nozzle holders and blasting gun mounts allow for customization based on the size and shape of the parts being coated. This adaptability ensures that every workpiece receives the same level of attention and precision during the blasting phase.

Integration with Curing Ovens

The final step in the powder coating process is curing. The design of the blast booth should seamlessly integrate with curing ovens. This ensures a continuous workflow and minimizes the handling of parts between processes. Proper integration also allows for consistent temperature and humidity control, which is critical for achieving a durable and attractive finish.

In conclusion, the impact of blast booth design on powder coating results cannot be overstated. From surface preparation to integration with curing ovens, each aspect of the design influences the quality and consistency of the final coating. By prioritizing factors such as contaminant control, workflow optimization, and adjustable components, manufacturers can achieve superior powder coating results that meet the highest standards of quality and durability. So, when considering powder coating equipment, don’t overlook the importance of a well-designed blast booth. It’s the key to achieving that flawless finish you desire.